We are LEIZHAN. We make excellent

dryer cylinders

Cast iron dryer cylinder diameter up to 3680mm, width up to 12000mm.Body material is HT250-HT350, the grade of ductile iron is QT400-QT600, the hardness is up to HB190-280.Steel dryer cylinder diameter up to 7500mm.the press roller diameter up to 1800mm.

Drying cylinder design and produce implementation standards: American national standard (ANSI), European standard (EN), German standard (DIN), French standard (NF), British standard (BS), Japanese industrial standard (JIS), Russian standard (POCT), Chinese National standard (GB) and other national standards.

Download our product and service introduction files to know more.

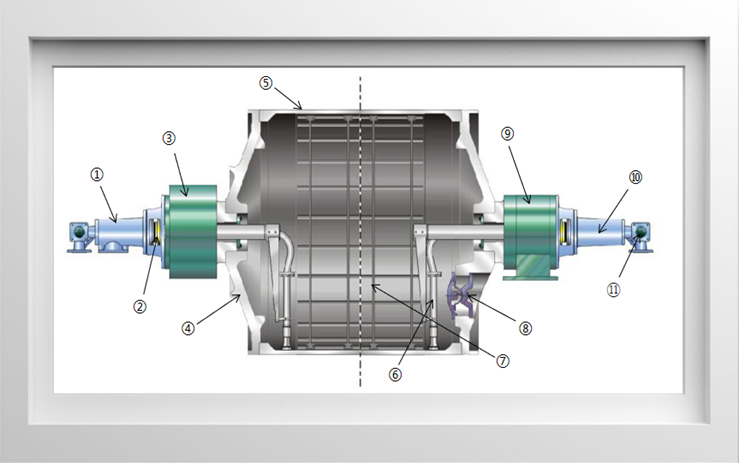

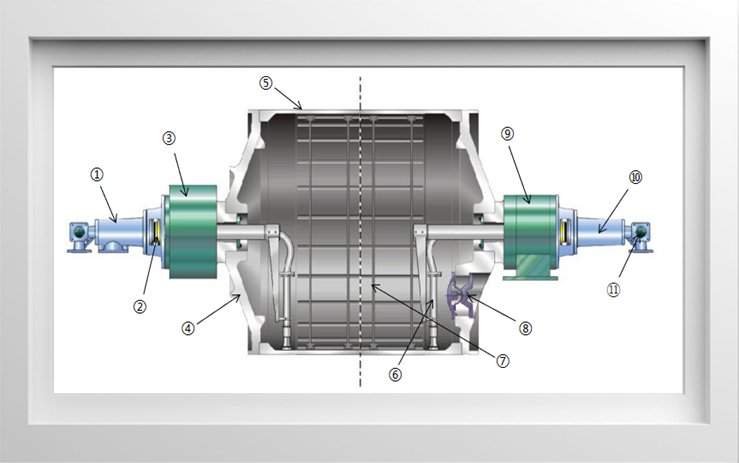

Four “Hearts” Of The Yankee Dryer Cylinder

Shell

Head cover

Turbulator & Siphon System

Metal coating

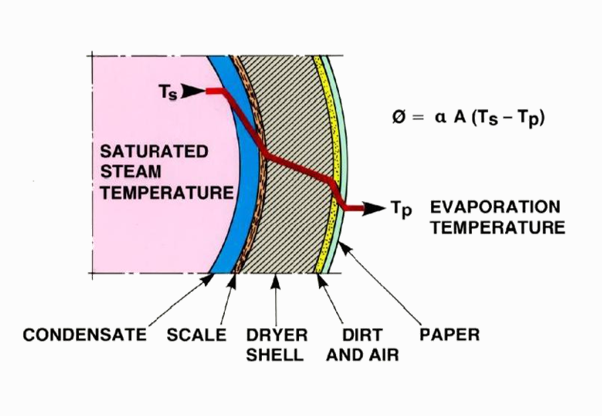

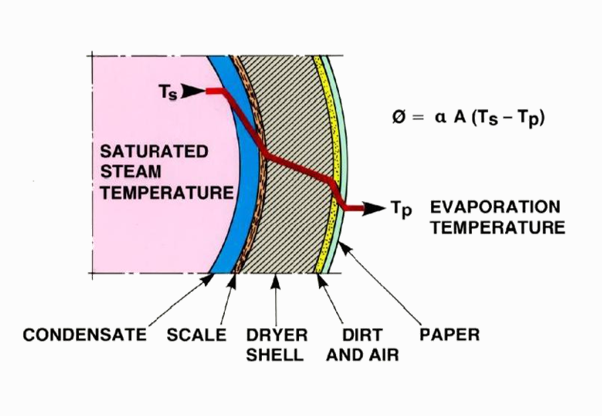

Heat Transfer from Steam to Paper

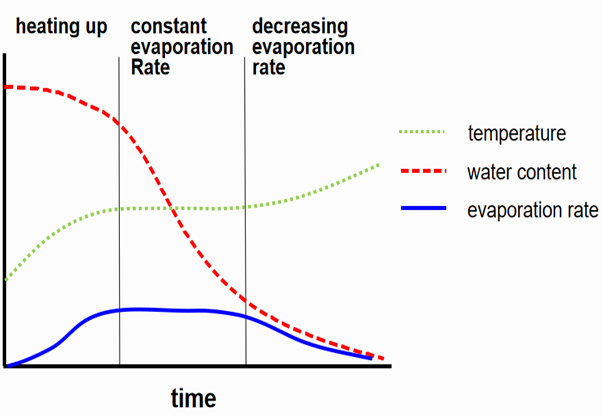

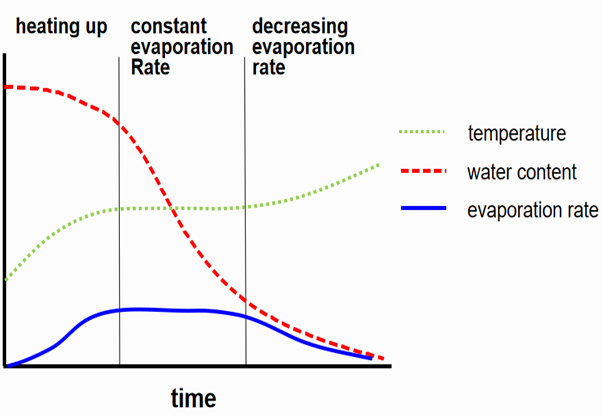

At present, most paper machines use steam heating dryer cylinder to provide heat energy, in the way of heat conduction, heat energy is transferred to the paper through the dryer. The humidity is generally from 60% reduced to 5% when the paper coming out from the dryer section, and then into the glazing machine.

Cast iron dryers

Cast iron dryer cylinder diameter up to 3680mm, width up to 12000mm.Body material is HT250-HT350, the grade of ductile iron is QT400-QT600, the hardness is up to HB190-280.

Steel dryers

Steel dryer cylinder diameter up to 7500mm, width up to 6500mm.Body material is carbon steel.Working pressure above 1.0MPa.

Advantage

are excellent in durability. This is because the free form flake graphite in the cast iron material ensured its high corrosion and erosion resistance. The cast iron also has good fatigue strength under the pressure roller forces. At the same time, cast iron itself has a good surface performance, does not need metal spraying treatment like steel dryer.

Advantage

can effectively reduce the thickness of the shell, the internal unique groove design can greatly improve the heat transfer efficiency, increase productivity, and decrease energy consumption. Steel material is characterized by ductility, which makes it safer to use on pressure vessels. The surface perfectly combines with the special alloy coating, suitable to produce high-quality paper.

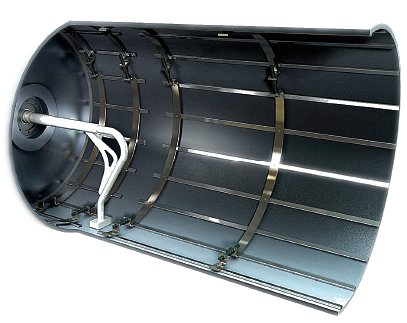

Grooved internal surface

We provided grooved internal surfaces Yankee dryer for customer choice. The Grooved Yankee dryer internal face is machined with radial grooves, condensed water accumulates in the grooves during running. It is used with a condensate extractor, each siphon on the extractor is located in the groove so that the condensed water can be effectively discharged. Under the same working condition, the grooved internal surface has good heat transfer efficiency and less steam loss than the smooth internal surface because of the reduced thickness at the root of the shell. This design can be applied to the paper machine's speed within 2200m/min.

Grooved cast iron dryer shell

Smooth internal surface

Grooved steel dryer shell

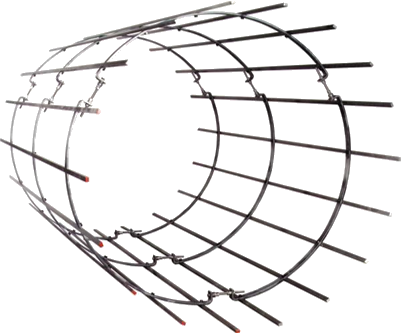

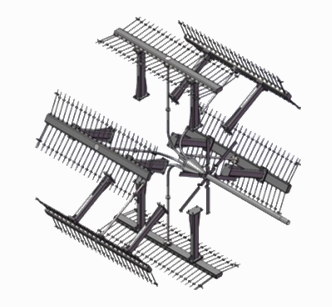

Condensate discharge device

Siphon selection is an important factor to maximize drying rate and reduce temperature variation.

Stationary siphon

The pressure difference requirement of stationary siphons is relatively low. The pressure difference required for cantilever stationary siphon does not increase with the increase of paper machine speed.

Condensate water can be discharged without use high pressure steam power in the case of air inlet pressure and pressure difference close to or lower than atmospheric pressure, it can reduce the corrosion.

Cantilever stationary siphons are usually suitable for medium to high speed paper machines.

Condensate extractors

The condensate extractors applied on grooved internal surface Yankee dryer cylinder.

It is supported by solid structures which ensure the required frame rigidity.

The entire system is designed to compensate thermal expansion and provide high wear resistance.